ACTUALLY… a more resource-efficient society will be achieved by using materials that are circular and do not become waste.

In the last five years the packaging landscape has changed dramatically driven by a legislative and public pressure to achieve a more circular economy.

The use of renewable materials remains in line with a linear pattern of consumption, where materials must be thrown away and replaced. In the case of wood used for paper or board, replacement materials can take up to 60 years to grow back or even be irreplaceable in the case of virgin forest[1].

| As such, we maintain that the most environmentally friendly packaging is that made from materials that can be recycled multiple times, rather than renewable materials. |

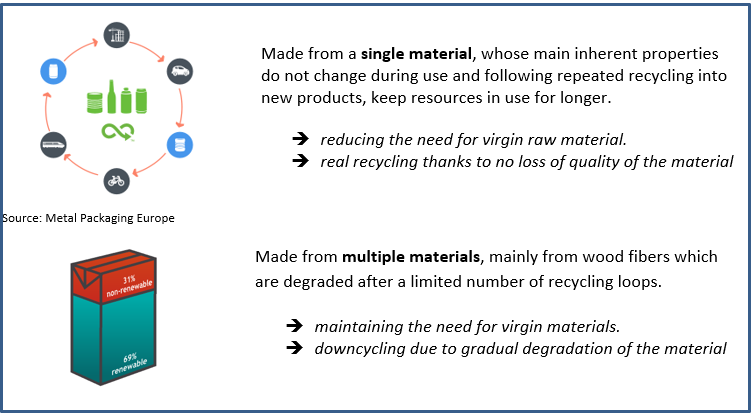

Circular design calls for a closed loop, where resources are repurposed; a process in which resources are continuously cycled in various forms, following a reuse or recycle loop. These resources do not go to waste.

As far back as 2012, the European Parliament voted to categorise steel alongside other metals in a new resource category of “permanent materials”, alongside the existing resource categories of “renewable” and “non-renewable”. More recently, the European Parliament highlighted the concept of permanent materials in its report on the Commission’s Circular Economy Action Plan 2.0, recognising their key role in the transition from a linear to a fully circular economy.

A permanent material is defined as one whose inherent properties do not change during use and despite repeated recycling into new products. Its recycling does not necessarily require the addition of primary material or additives to enable the basic material function and properties[2].

Through their ability to recycle multiple times, products and packaging made from permanent materials, such as steel, are kept in the material loop becoming resources for other products and packaging, over and over again.

Steel produced decades ago can still be recycled today and used in the manufacture of new steel products – a train, car or even another can. Indeed, worldsteel estimates that 75% of steel ever made is still in use.

When you take into account this multiple recycling rather than the one recycling loop currently used for LCA studies, the global warming potential (GWP) of hot-rolled and hot-dip galvanized sheet steel is reduced by +/- 50%[3]

For more information, a detailed and precise categorisation of packaging materials was identified by the Swiss consultancy Carbotech together with an expert group from the metal packaging sector, in their 2014 report “Permanent Materials, Scientific Background”

[2] Permanent materials, final report, Carbotech AG 2014

[3] ÖKOBILANZ NACH ISO 14040/44 FÜR DAS MULTIRECYCLING VON STAHL (Sabrina Neugebauer, Prof. Dr. Matthias Finkbeiner)