Contrary to what some competing materials would like you to believe, the steel can is clearly here to stay driven by unrivalled successes in recycling and unbeatable product protection.

As we recognise the benefits of a more circular economy, and growing consumer concerns about packaging coincide with businesses conscious of the size of their environment footprint, it is understandably difficult to choose between the range of packaging options available on the market.

Some lightweight materials appear to offer attractive environmental benefits and short-term financial savings in transport for example. But it’s worth taking a closer look at what happens at the end of the packaging life-cycle in order to see the full environment picture.

Let’s take the example of retortable cartons.

Let’s take the example of retortable cartons.

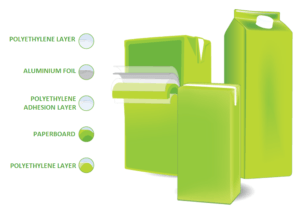

Whilst appearing to be made from easily-recycled cardboard, they are in fact a multi-layer sandwich of paper, aluminium and low-density polyethylene among others. Whilst it is possible to recycle each of these materials, they have to be separated first; a difficult and costly process which few recyclers are equipped or prepared to carry out.

In addition, a carton’s fibres become shorter every time they are recycled – which means that after seven recycling loops on average, there is nothing left – a finite life cycle that spirals down into end of life.

(Image source: ACE)

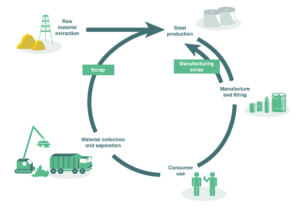

Steel, on the other hand, is a permanent material whose inherent chemical and physical properties do not change, regardless of how many times it is recycled.

Steel produced as much as 150 years ago can still be recycled today and used in the manufacture of new products. Indeed, Worldsteel estimates that 75% of the steel ever made is still in use today.

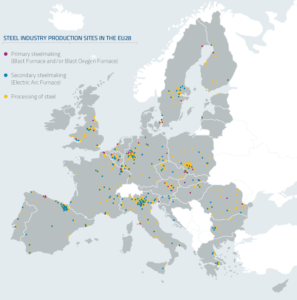

Unique magnetic properties make steel the easiest and most economical packaging material to recover from any waste stream, all you need is a magnet. And since scrap is a necessary component in the process of new steel, every single steel plant – and there are over 500 of them in Europe – is also a recycling plant. Only six facilities across Europe carry out the ‘full separation’ recycling procedure of cartons in which the polymer and aluminium fraction are also recovered1.

Of course, the environment was of less concern to the pioneers of canned foods two centuries ago whose principle objective was to preserve food supplies as effectively as possible. That need persists to this day and, even after 200 years, no other packaging material has emerged that equals steel’s strength, total barrier properties or shelf life. Food packed in steel stays fresh for longer, retains its flavour and is less likely to be damaged, spoiled, or unnecessarily wasted.

(Image source: Eurofer)

Far from being past it’s best, steel it seems, is only just beginning to fulfil it’s potential. Will we be saying the same about some other materials in 200 years’ time?

- (source: Alliance for Beverage Cartons and the Environment. (n.d.). Process and products. Retrieved from: www.ace.be)