Steel is not the first packaging material that springs to mind for Nordic packaging markets, long influenced by local carton and board producers.

But a strong environmental focus is endemic to the Nordic countries. So, when Secretary General Alexis Van Maercke joined the session focused on EU and Politics at our first ever Scanpack event last October, he found a receptive audience keen to learn more about upcoming EU waste legislative initiatives, the real circularity of steel and APEAL’s vision of zero waste to landfill by 2025.

In the drive to keep nutritious food affordable for all, the efficiency of steel cans is re-gaining importance with many brands and consumers, even in a market where rival packaging formats have regularly sought to distort consumer perception.

As the strongest of all packaging materials, steel provides unrivalled protection for products against crushing, perforation, and breakage. Steel’s 100% barrier against light, water and air ensures the longest product shelf life of any packaging material, up to 5 years for some products.

And, an important element in the context of the world’s current energy crisis, refrigeration-free transport and storage help to reduce energy consumption throughout the supply chain and at home.

Today, steel makers across Europe are revolutionising primary production processes in the EU to reach carbon-neutrality by 2050 at the latest, with relevant CO2 emissions reduction targets by 2030. And with a 85,5% recycling rate average across Europe, 87% average across Norway, Sweden, Finland and Denmark, full circularity is another strong reason for using steel across all product categories.

As we head towards a more sustainable future, steel provides a multiple and fully recyclable solution across the board.

As we head towards a more sustainable future, steel provides a multiple and fully recyclable solution across the board.

Read more (in Swedish) here

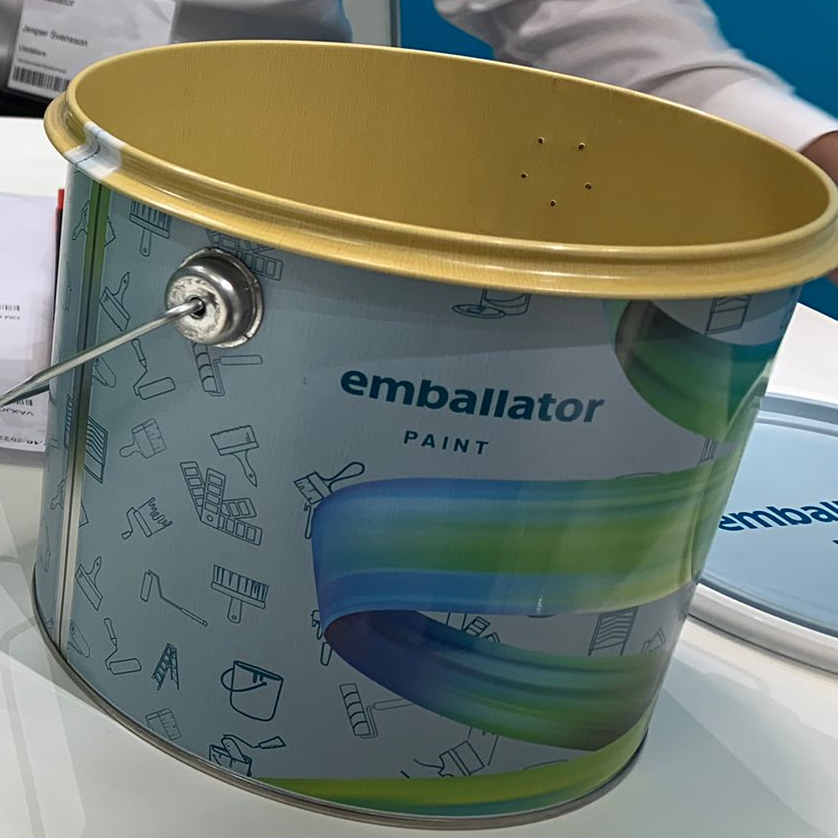

Emballator group latest steel innovations for paint cans at the Scanpack show