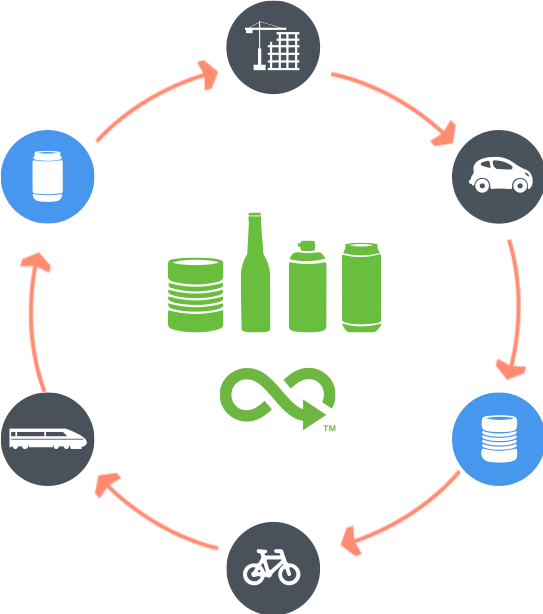

Actually…Recycled content does not mean recyclability. Both are needed to achieve an ever-recurring material cycle that prevents waste

Demands for increasing recycled material content in packaging are gathering momentum.

But the focus of a recycled content approach is on a product’s previous life. It does not guarantee that the current product will be recycled when it reaches the end of its current life.

Even if a product is made with very high recycled content, if there is no demand for its constituting materials at the end of its life, and it is not recycled again, the embedded resources & energy used to manufacture it will go to waste.

When scrap demand exceeds supply, as in the case for steel, the best strategy is to focus on a metric such as recycled rate in order to increase the availability of scrap. |

Recycled content can be a useful measure for materials where the amount of available scrap exceeds market demand, working as a mechanism to incentivise the use of scrap rather than virgin materials. That is, for example, the case for plastics. If manufacturers can ensure that products have a higher rate of recycled content it can be a way to reduce excess waste and prevent more raw material being brought into the loop.

Indeed, recyclability in theory is not the same as being recyclable in practice.

When packaging is marketed as «can be recycled», we must ask “is it really recycled”?

- Is it recyclable in a few places or widespread?

- How easy is to separate each part / material?

- Is it entirely recyclable or are some parts difficult to recycle?

- Is it recyclable once, twice or indefinitely?

- Is it economically viable to recycle it or does it need subsidy?

Indeed, many materials claim to be 100% recyclable but the process is neither economically viable nor producing an output material with a clear market. This is the current dilemma with plastics, or the output of the plastics/aluminium alloy derived from recycling cartons.

On the other hand, the steel used in packaging, whether for food cans, beverage cans, aerosols, household products or closures is a material that is really recycled and used to make new products such as cars, buildings, wind turbines or even new packaging. There is a clear demand and an attractive value.

Steel is 100% recyclable, and 84% of steel packaging is currently recycled vs a recycling rate of 51% for cartons[1] or 41% for plastics[2]. In addition, steel packaging can be recycled over and over again, contrary to other packaging materials that lose their qualities when recycled and manage only a finite number of recycling loops at best.

Because steel scrap is a necessary component in the process of new steel every single steel plant is already also a recycling plant. As such, there is a clear market for all scrap steel collected and more than 500 recycling plants in Europe recycling steel is a well-established and efficient process.

Because steel scrap is a necessary component in the process of new steel every single steel plant is already also a recycling plant. As such, there is a clear market for all scrap steel collected and more than 500 recycling plants in Europe recycling steel is a well-established and efficient process.

At the same time new legislation is preparing additional requirements likely to impact not only the reporting of recycling figures for composite packaging but also their calculation.

Zero Waste Europe estimates that one issue for many packaging formats, in particular cartons, is that while the ‘placed on the market’ weight (the denominator in the recycling rate calculation) is pure packaging, the ‘recycled’ weight (the numerator in the calculation) often includes other elements, such as food and drink remaining in items of packaging, or dirt and other contaminants “stuck” on or inside the package.

Under the EU’s new measurement method for recycling, applicable for data from 2020, to be reported from 2022 onwards, all such process losses will have to be deducted from material counted within recycling figures. As such we expect recycling rates for composite materials such as cartons to decrease even lower than today

[1] https://www.beveragecarton.eu/news/ace-announces-increased-recycling-rate-for-beverage-cartons/

[2] 2019 Eurostat data