Actually… Flexible packaging means products are at greater risk from damage and loss.

With the environmental burden of packaged food dominated by the content (>90%) the protection of the content is of utmost importance.

As the strongest of all packaging materials, steel cans are more stable and resistant during handling and transport than lighter packaging materials, means less risk of damage or loss for the products they contain.

Palettes of filled cans can be stacked on top of each other, evenly and with minimal secondary packaging.

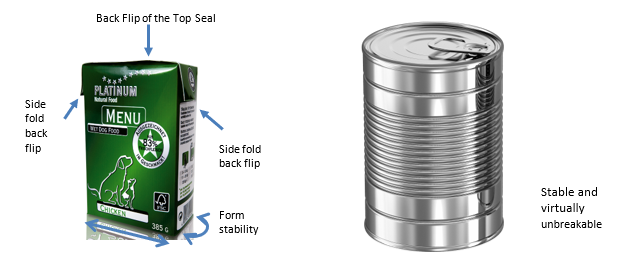

In contrast, form stability is an issue for flexible packaging formats that also require more rigid secondary packaging for protection.

Cartons, for example, have top and side flips that generate instability and height variations of up to 3-4mm that could have a large impact on the in-truck load per palette and lead to problems during packing.

In their 2018 study for Metal Packaging Europe, Tilisco estimates that up to 4 filled pallets are possible with cans in a storehouse and truck compared to 1 for cartons. At the same time, the axial load limit was found to be 10 times higher for cans than for beverage cartons, being 3000N vs 300N.

In their 2018 study for Metal Packaging Europe, Tilisco estimates that up to 4 filled pallets are possible with cans in a storehouse and truck compared to 1 for cartons. At the same time, the axial load limit was found to be 10 times higher for cans than for beverage cartons, being 3000N vs 300N.

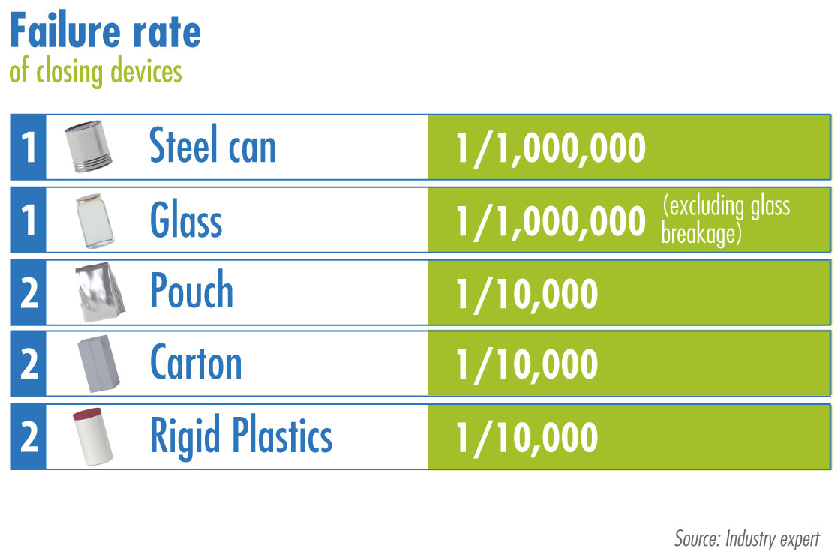

When it comes to reliability, Tilisco calculated that although an extra 3,7% cartons could be transported in a 25T truck, relative to cans, measured failure rates show that the product transported inside the cans was 100 times safer from risk of failure.

In addition, up to 2% of multi-layer cartons are estimated to be lost during filling[1], which is incomparable to the 0,1% can filling loss rate. Remembering that steel cans can be filled at a standard rate of 500 cans per minute, compared to a maximum of 400 per minute for multi-layer cartons.

All procedures of storage, handling and transport can be carried out at ambient temperature, meaning that shipping and storing canned fruits and vegetables require a less energy-intensive cold chain distribution system than fresh, chilled and frozen.

When it comes to food waste in the home, steel cans also benefit from better emptiability purely by the very nature of their opening. Whilst there is no formal research on the subject of food cans as yet, Bernhard Wohner was one of the first to analyse the effect of food loss from poor emptiability of flexible packaging relative to rigid packaging in his 2020 study[2]. He estimated the increase in food waste to be between 3,85% – 28,8%.

Find out more

steelforpackaging.org, a dedicated website highlighting the benefits of steel as a packaging material and showcasing innovation across the industry.

[1] SSICA (Experimental Station for the Food Preservation Industry – Research Foundation)

[2] Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup, Bernhard Wohner, https://www.researchgate.net/publication/341803211_Environmental_and_economic_assessment_of_food-packaging_systems_with_a_focus_on_food_waste_Case_study_on_tomato_ketchup