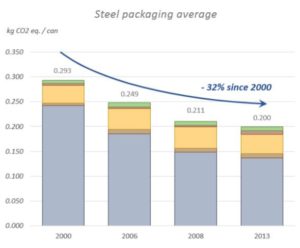

#19.10.2016 STEEL CANS HAVE REDUCED THEIR CLIMATE CHANGE IMPACT BY ALMOST ONE THIRD SINCE 2000

APEAL, the Association of Producers of Steel for Packaging, has confirmed that the impact on climate change of the average unit of steel packaging was reduced by 32% during 2000 – 2013.

APEAL, the Association of Producers of Steel for Packaging, has confirmed that the impact on climate change of the average unit of steel packaging was reduced by 32% during 2000 – 2013.

A recent Life Cycle Assessment (LCA) of cans, conducted by Empac, European Metal Packaging, has revealed continuous improvement in the carbon footprint of steel cans across all the five product categories analysed – food cans, aerosols, general line cans, closures and speciality tins.

The reduction in CO2-equivalent has been attributed by Empac to three factors:

- Continuous improvement in recycling rates,

- Continuous improvement in unit light weighting,

- Increased amounts of green energy used for the packaging manufacturing process.

The study also measured the net water consumption, which is a key component when assessing a product’s environmental footprint. The results confirm that steel packaging reduced impact on water depletion by an impressive 60% per average unit between 2006 and 2013.

Stéphane Tondo, President of APEAL, said: “Life cycle thinking is vital for the future and for moving towards a circular economy.

“This new study demonstrates how steel as a material contributes to the sustainable development of the can. It is important that our customers, and all our stakeholders, have the full picture so that they can make informed and sustainable choices about packaging.”

The Empac LCA on metal packaging – which is ISO 14040/44 compliant – was conducted by RDC Environment, an independent international consultancy firm based in Brussels, and peer-reviewed by Solinnen, a Paris-based consultancy company specialised in LCA practices.

In addition to APEAL, 74 can manufacturing sites across 16 countries contributed their 2013 data.

APEAL’s complete LCI dataset is included on the The Life Cycle Data Network (LCDN), the International Platform for life cycle data launched by the European Commission in 2014 and is also available at www.apeal.org. Providing a cradle to gate analysis of all the European tinplate production steps from the extraction of raw materials to manufacturing of the coil, it is the European reference dataset for tinplate and the only one to be used for relevant and up to date studies.